-

Uniade's chicken is the best in the market

You know why?

Because the birds are created according to the animal welfare standards following stringent ambience controls and plant sanity.

-

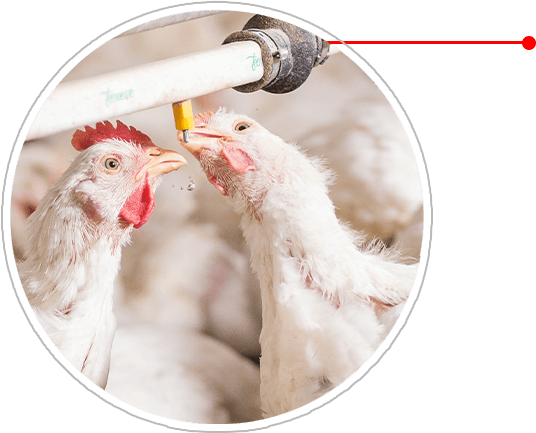

The monitoring of the productive chain begins in the farms of recreation, following the farms of fertile eggs. These eggs are sent to the incubatory for the development of embryos and birth of chicks, within rigorous moisture patterns, temperature, ventilation and hygiene.

In this way the chicks are transported in thermal trucks and housed with producers in the Serra Capixaba region, integrated with the UNIAVES PARTNERSHIP system , to which it remuners for this important stage of the process.

-

As an important part of this work, the ration is 100% produced by uniads the basis of corn and soybean bran and enriched with vitamins and minerals.

-

At 45 days, the birds will be ready for slaughter that will be held at the modern slaughterhouse of Uniaves located in Castle.

From the aviary to the delivery of the chicken to the point of sale, the company holds the full control of the steps and can crawl all products, always under the follow-up of the Federal Inspection Service (SIF).

-

It should be noted that by the characteristics of this region and the climate, water quality and due to the care provided by these producers and our technical veterinary team, we will have a healthy product and with a total guarantee of origin.

-

This slaughterhouse is listed among the most modern in Brazil and has a slaughter capacity of 160,000 birds / day.

-

When they reach the slaughterhouse, the loads of birds are accompanied by the batch follow-up form (FAL), equivalent to the bird's identity card, and are monitored by SIF veterinarians ensuring sanity and control of the creation information.

Animal well-being rules are applied and monitored by their own team and dedicated at short intervals ensuring the tranquility of animals for subsequent slaughter under humanitarian conditions.

-

Packaging are automatically prepared and labeled by ensuring the traceability of the product.

-

The slaughter process is fully automated and seeks to meet the requirements of consumers for practicality and quality. The machines have the manual support of highly trained professionals for the birds to be sectioned within rigid hygiene standards and controls ensuring the high degree of food safety of our products.

-

The products are destined immediately for a large freezing tunnel, ensuring its freshness. Every day, they are loaded into refrigerated trucks, previously sanitized and audited by our quality control team and SIF.

-

Thus, we guarantee our production with 100% traceability and within the most demanding standards of Food security.